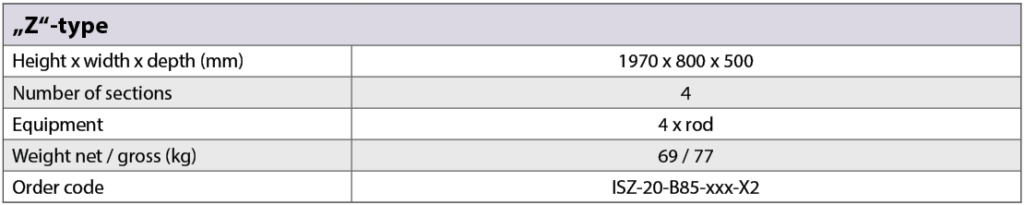

“Z“-type

Clothes lockers combining steel sheet and laminated chipboard offer a high-quality and reliable solution for changing rooms in a wide range of facilities, such as companies, schools, sports centers, hospitals, swimming facilities, and more.

The welded body, made of 0,8 to 1 mm thick steel sheet, ensures high rigidity and minimizes assembly demands.

Number of sections: 4

Equipment: 4x rod

Information

The clothes lockers are made of high-quality steel sheet with a powder-coated finish, combined with laminated chipboard in a selection of wood and color decors. All edges are finished with 2 mm ABS edging. The lockers have pre-drilled holes for optional shelf installation.

Perforations in the steel structure ensure effective ventilation. Lockers can be bolted together to create a compact, stable unit.

Thanks to their design and high-quality construction, clothes lockers made of steel and laminated chipboard provide a reliable solution for changing rooms in a variety of facilities, such as companies, schools, sports centers, hospitals, fitness clubs, and more.

Other decors are available in our sample book and can be used upon individual request.

The standard color palette for the steel frame includes RAL 7035 (light grey), RAL 5005 (blue), and RAL 9005 (black).

Decors, colours

Technical parameters

Recommended method of installation and maintenance of Triton lockers

Recommended environment:

- Intended for indoor use,

- The locker is not intended for outdoor installations and for installations in environments that can negatively influence the functionality of the locker (humid or wet environments).

Must be protected from:

- Mechanical damage,

- Improper handling,

- Different usage than the locker is intended for.

Improper handling is especially:

Interference with the construction and design of the locker.

Installation of the locker:

The locker must be placed on a flat floor; any small unevenness will be compensated by levelling feet. We recommend fixing metal furniture to the wall.

Environment protection:

All parts are made of recyclable materials and after decommissioning the locker, they must be disposed of according to relevant regulations.

Maintenance:

- It is recommended to wash the locker regularly with common non-abrasive detergents with a neutral pH (5-8) and then dry it thoroughly.

- The manufacturer is not responsible for normal wear and tear of the product.