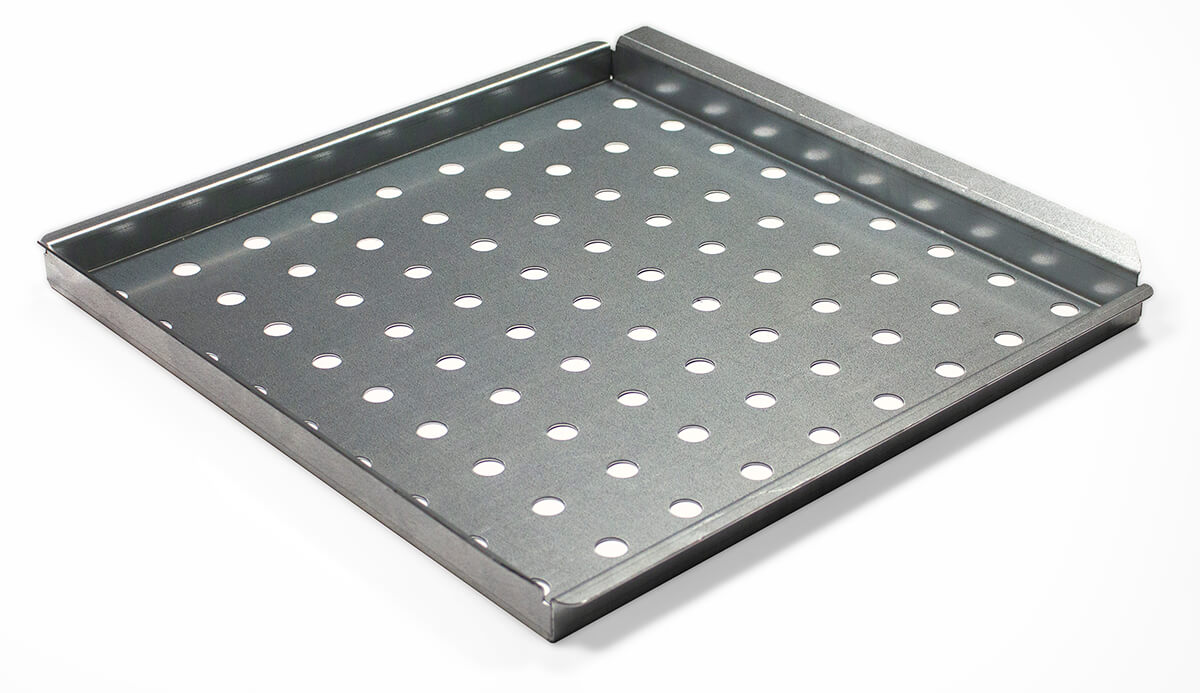

Ski and snowboard locker – 2/3 shelves

Ski and snowboard lockers, which can be equipped with additional accessories, are designed for ski rooms in hotels and mountain resorts. They are made of galvanized steel sheet coated with durable powder paint, and are available in standard RAL colors: RAL 7035 (light grey), RAL 5005 (blue), and RAL 9005 (black).

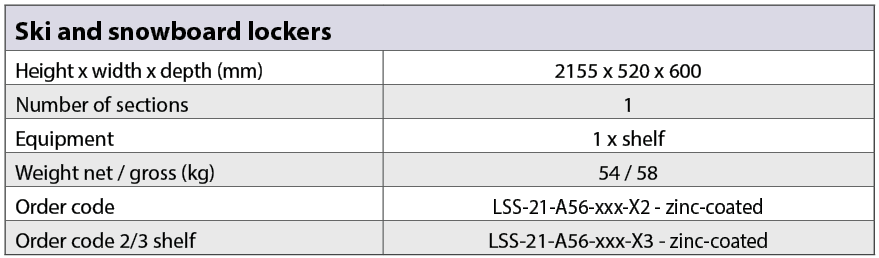

Number of sections: 1

Equipment: 1x shelf

Information

The ski and snowboard lockers are designed for ski rooms in hotels and mountain resorts.

The lockers are characterized by a sturdy welded construction made of galvanized steel sheet coated with durable powder paint. The rear panel is predesigned for integration with an effective boot drying system. Special perforations in the door and back ensure proper air circulation inside the locker.

The 2/3-shelf variant allows the full height of the locker to be used for storing long items.

The lockers can be equipped with a galvanized slope tray or a grid.

Drying system

Drying systems for boots, ski boots, and rubber boots work on the principle of continuous circulation of warm air, which is blown directly into the item being dried.

Warm air at approximately 45°C (with an ambient temperature of 15°C to 25°C) provides fast, hygienic, and safe drying.

The dryers are manufactured as standard with an analog timer that allows the shutdown time to be set from 1 to 120 minutes.

These drying systems have a wide range of applications across various industries, such as fire departments, chemical laboratories, construction companies, industrial facilities, agricultural facilities, hotels, cabins, guesthouses, road maintenance services, military, police, hockey clubs, football clubs, and more.

Accessories

Decors, colours

Technical parameters

Recommended method of installation and maintenance of Triton lockers

Recommended environment:

- Intended for indoor use,

- The locker is not intended for outdoor installations and for installations in environments that can negatively influence the functionality of the locker (humid or wet environments).

Must be protected from:

- Mechanical damage,

- Improper handling,

- Different usage than the locker is intended for.

Improper handling is especially:

- Interference with the construction and design of the locker.

Installation of the locker:

- The locker must be placed on a flat floor; any small unevenness will be compensated by levelling feet. We recommend fixing metal furniture to the wall.

Environment protection:

- All parts are made of recyclable materials and after decommissioning the locker, they must be disposed of according to relevant regulations.

Maintenance:

- It is recommended to wash the locker regularly with common non-abrasive detergents with a neutral pH (5-8) and then dry it thoroughly,

- The manufacturer is not responsible for normal wear and tear of the product.