IPO

IPO clothes lockers specially designed for firefighters and rescue services guarantee immediate availability of emergency clothing whenever needed. The lockers are made of welded galvanized steel construction and can be supplied with feet and a special folding helmet holder at an additional cost.

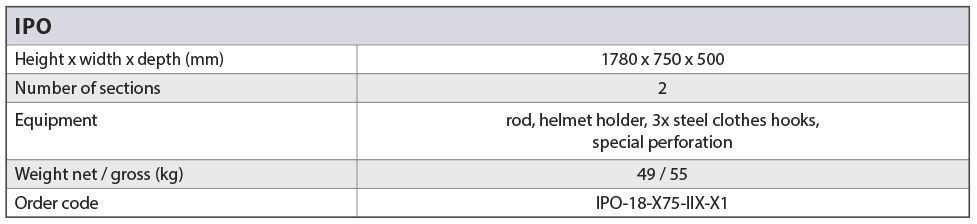

Number of section: 2

Equipment: 1x rod, 1x helmet holder, 3x steel clothes hooks and special perforation

Information

Two section fire assymetric composition IPO type in RAL 3000 colour with and galvanised grate, specially made for firefighters and rescue services, which guarantees immediate availability of emergency clothing whenever needed. Assamble construction made of 1 to 1,3 mm thick galvanised steel and supplemented by perforation of the sides to ensure the highest possible ventilation of clothing.

We recomended to hang the IPO type closets on wall or equip them with feet with leveling screws.

The feet with rectifying screw are not a standard equipment of lockers, they can be purchased separately. The height of the feet is 100 mm. They can be supplied in black or red colour.

The lockers can be equipped with a special tiltable helmet holder for additional charge. By simply pulling on the helmet, the holder tilts down and it is much easier to remove.

Technical parameters

Recommended method of installation and maintenance of Triton lockers

Recommended environment:

- Intended for indoor use,

- The locker is not intended for outdoor installations and for installations in environments that can negatively influence the functionality of the locker (humid or wet environments).

Must be protected from:

- Mechanical damage,

- Improper handling,

- Different usage than the locker is intended for.

Improper handling is especially:

- Interference with the construction and design of the locker.

Installation of the locker:

- The locker must be placed on a flat floor; any small unevenness will be compensated by levelling feet. We recommend fixing metal furniture to the wall.

Environment protection:

- All parts are made of recyclable materials and after decommissioning the locker, they must be disposed of according to relevant regulations.

Maintenance:

- It is recommended to wash the locker regularly with common non-abrasive detergents with a neutral pH (5-8) and then dry it thoroughly,

- The manufacturer is not responsible for normal wear and tear of the product.